Production Technology

We will contribute to the Japanese manufacturing industry by providing high-quality products required by our customers with high production technology.

Our products are created through our technologies for cold forging, design and development, and quality control, as well as through our in-house integrated production system. This enables us to provide high-precision, high-strength, and high-quality parts that support the security and safety of automotive parts at a low cost.

We will contribute to Japan's manufacturing industry by inheriting our advanced production technologies into the future and engaging in new technological innovations.

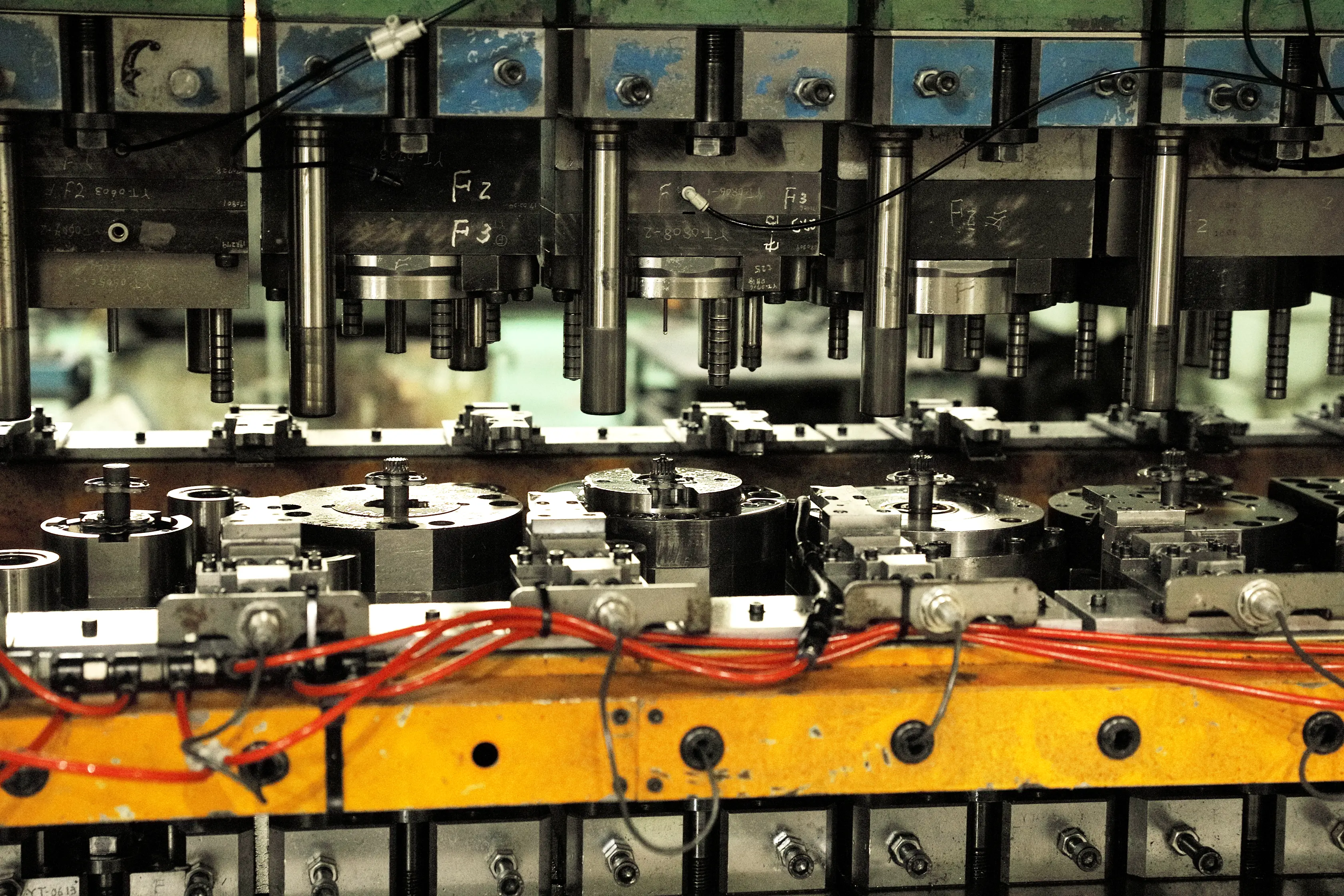

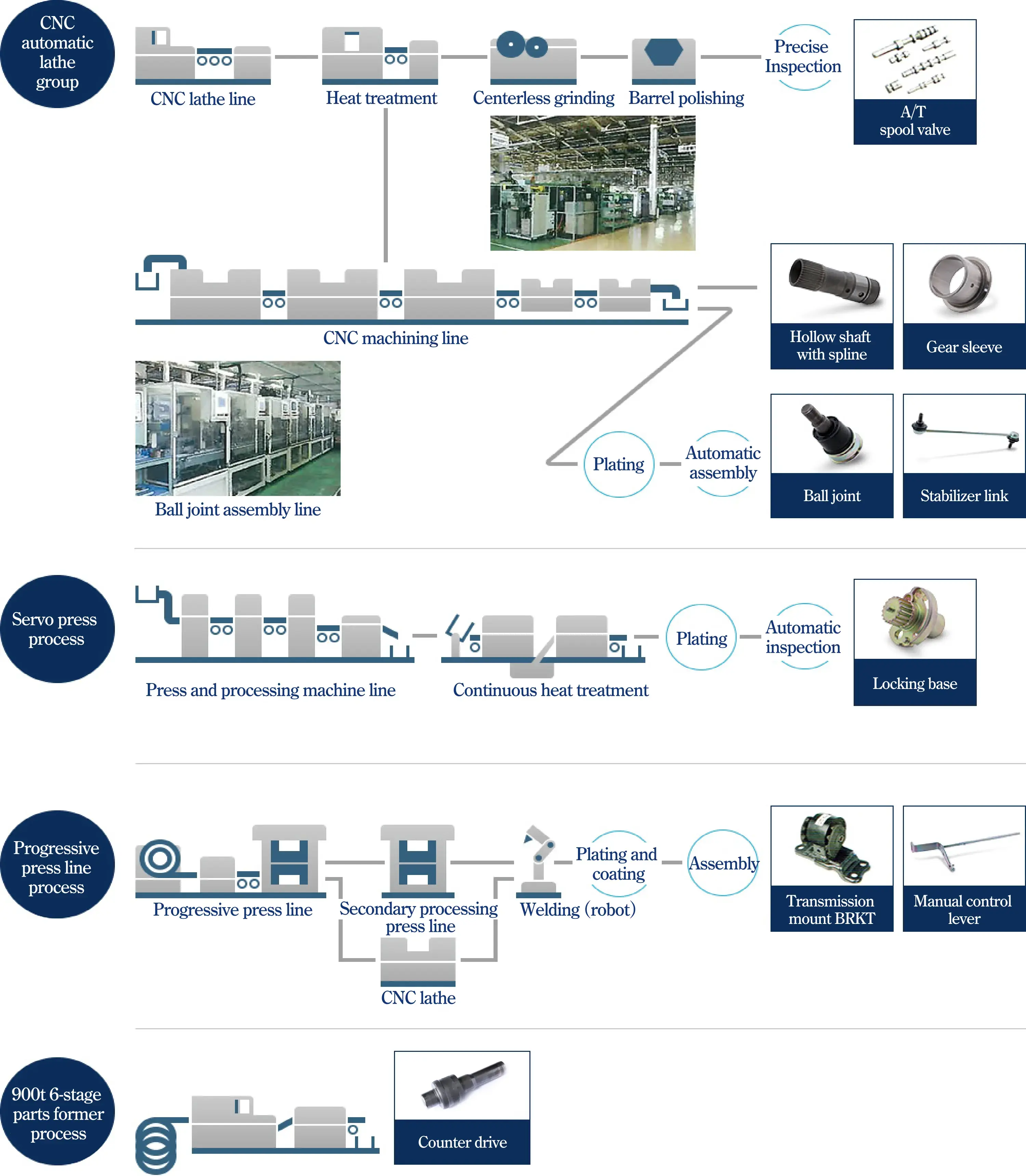

Integrated production system

We can produce everything from material processing to heat treatment, machining, welding, and assembly. Since we are able to complete all of our products in-house, we are able to utilize our advanced technological capabilities and know-how cultivated over many years in all processes, and we are able to consistently guarantee the quality of each process.

We manufacture automotive parts, which are used for human life, therefore we continue to refine our reliable technological capabilities so that we can continue to supply high-precision, high-strength parts to our customers.

-

Heat treatment

-

Machining

-

Surface treatment

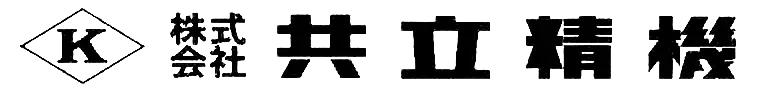

Cold forging technology

Using our cold forging technology, we can shape the material as close to the shape of the final product as possible. Therefore, machining is minimized, and production with reduced product costs is possible. In addition, with this technology, since molding is performed in the mold, products with stable accuracy can be produced, ensuring high quality.

For more than 40 years, we have cultivated ourselves with this technology as our core technology. We will continue to pursue further evolution with more passion than ever before.

-

Surface treatment

-

Part former

-

Cold forging

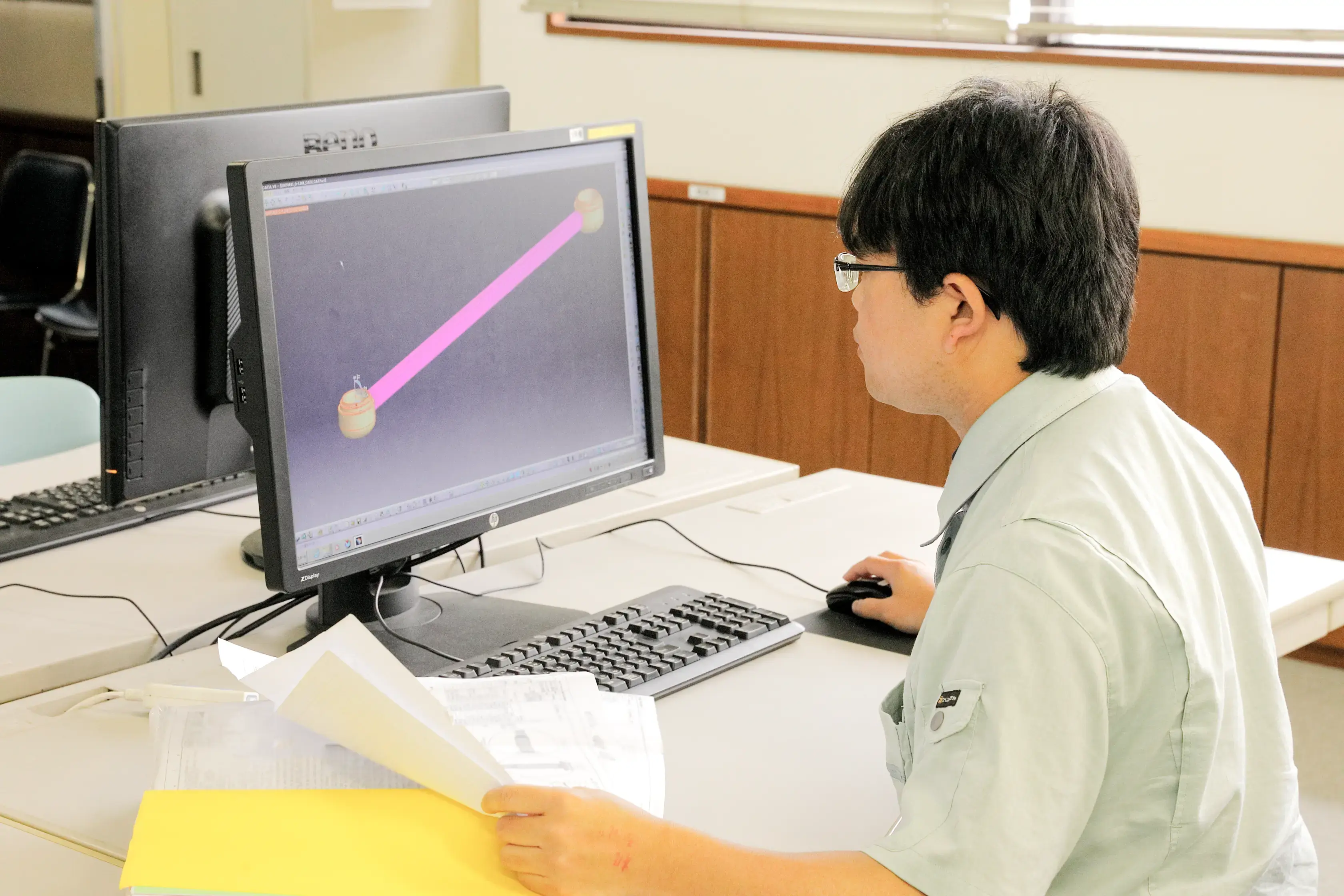

Design and development

We design and develop stabilizer links and ball joints by in-house design and development personnel. As a result, we are able to carry out design and development that makes maximum use of our technologies, and this is a major strength. We also conduct in-house performance evaluation tests on products designed and developed ourselves. We provide high-quality products that satisfy the performance requirements of our customers by taking responsibility for the entire process from test to evaluation.

-

Environmental testing equipment

-

In-house designed products

Quality Control

To earn the confidence of our customers, we acquire global quality management system IATF16949 and conduct quality control based on them. In addition, we are thoroughly implementing quality control on-site through employee education on quality control and the introduction of strict quality standards. Furthermore, we sincerely face customer feedback and implement prompt and appropriate measures to prevent a recurrence. Through these initiatives, we will produce high-quality, safe and reliable products.

-

Salt spray testing equipment

-

Coordinate measuring machine

-

Finished product inspection

Manufacturing process

Equipment owned

-

- Name

- Form and ability

- Number of equipment

-

- Parts former

- 200t ~ 900t

- 5

-

- Cold forging press

- 160t ~ 650t

- 8

-

- Sheet metal press

- 60t ~ 300t

- 15

-

- Servo press

- 200t 、400t

- 2

-

- CNC lathe

- 126

-

- NC automatic lathe

- 30

-

- Machining center

- 13

-

- NC sharpening machines

- 45

-

- Thread rolling machine

- 20

-

- Heat treatment

- Continuous furnace, batch furnace

- 10

-

- Welding machine Arc

- projection

- 40

-

- Resistance welder

- Butt welding

- 10

-

- Ball joint, stabilizer link assembly machine

- 8

-

- Magni coating equipment

- 1

-

- Durability tester

- 6

-

- Environment tester

- 1

-

- Neutral salt spray testing machine

- 1